All pieces slotting right in

The only thing nobler than preparing for a perfect future is if you can also make your present a little better in the process. The e-gas project by Audi goes to show that alternative technologies should not compete against but rather complement each other.

The only thing nobler than preparing for a perfect future is if you can also make your present a little better in the process. The e-gas project by Audi goes to show that alternative technologies should not compete against but rather complement each other.

The whole story started some four years ago for Audi, and the underlying rationale was just as purely logic-driven as their cars. Obviously, there are two major issues with petroleum-based fuel: one is that the oil reserves of our planet are eventually going to run dry, and the other one is that by using these fuels we cause serious damage to the environment. That means we need a solution to these problems not tomorrow but right now; yet at the same time a technological paradigm shift is inevitable in the long run.

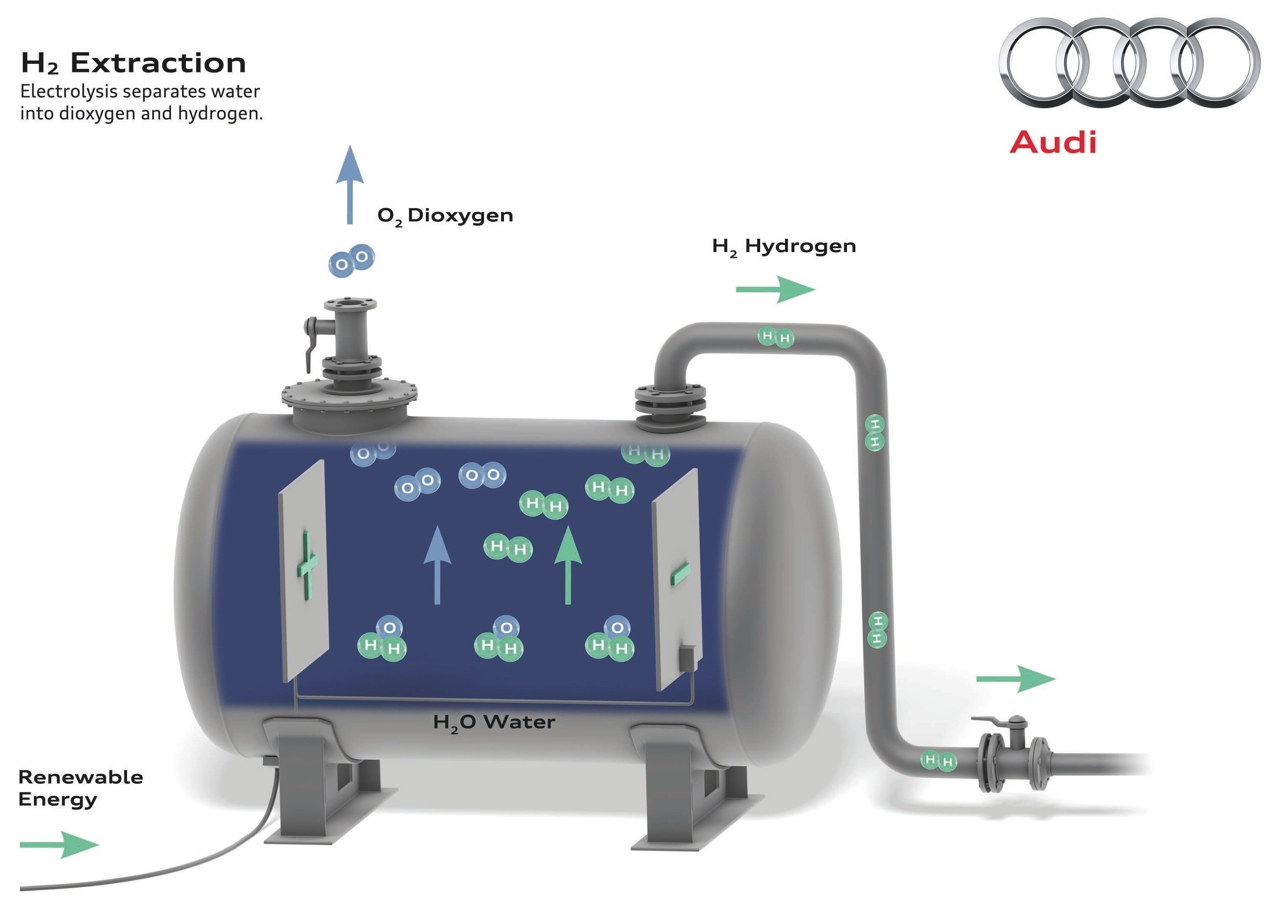

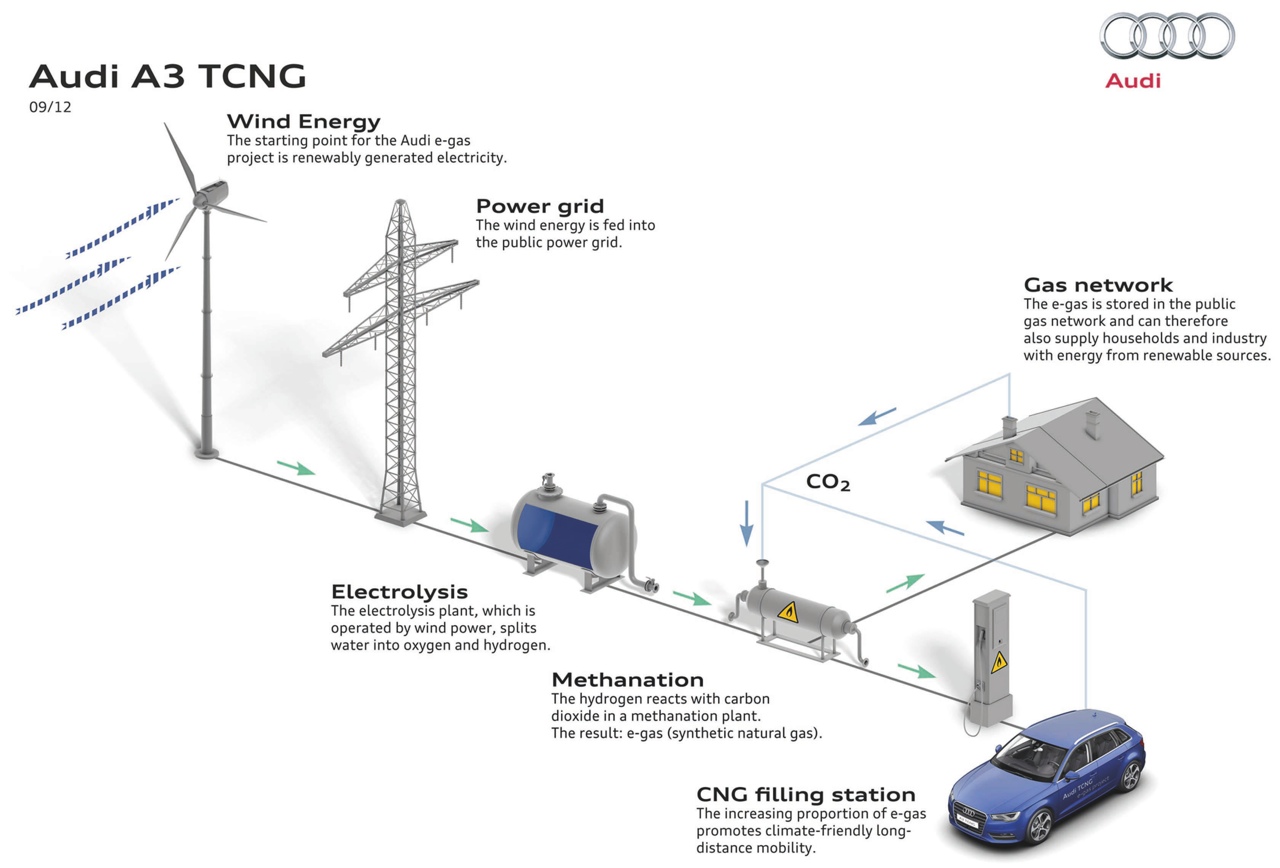

Audi's e-gas project combines the demands of the present with the requirements of the future in a complex yet logical system. The long term objective of the project is to ensure the emissions-neutral production of hydrogen. As a first step towards this goal Audi has invested significantly in wind power plants on the North Sea enabling them to use electricity from a renewable source to create hydrogen from water (this is important because electrolysis is a rather energy consuming process which, if powered by power plants running on fossil fuels, can make the overall well-to-wheel emissions balance of hydrogen rather unfavourable).

All of this is brilliant, except for a minor detail – at the moment, clean mobility using liquefied or gaseous hydrogen in either an ICE or a fuel cell is nothing more than a highly promising experiment. In fact hydrogen-based motoring is only a few small steps away from the point where its wide-spread marketing is "only" blocked by the lack of infrastructure or available funds.

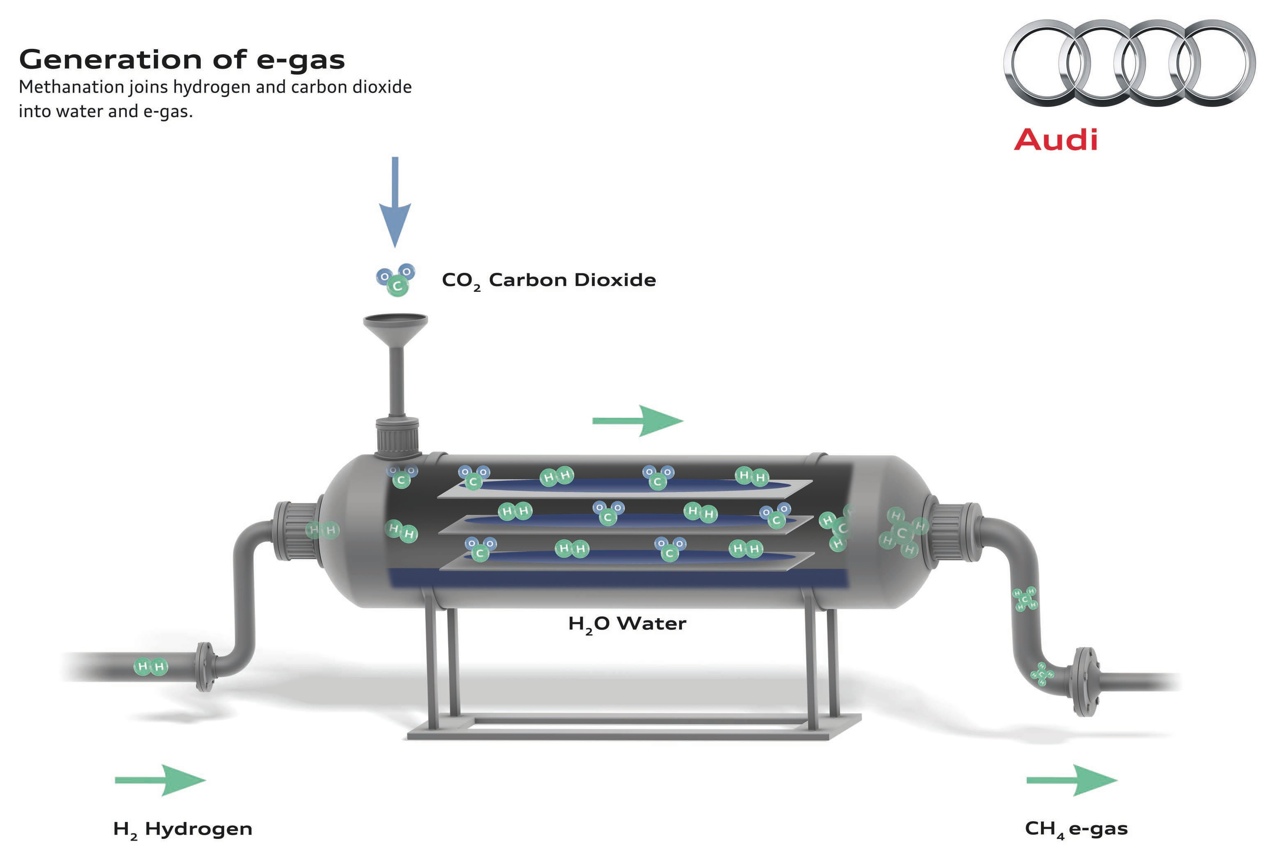

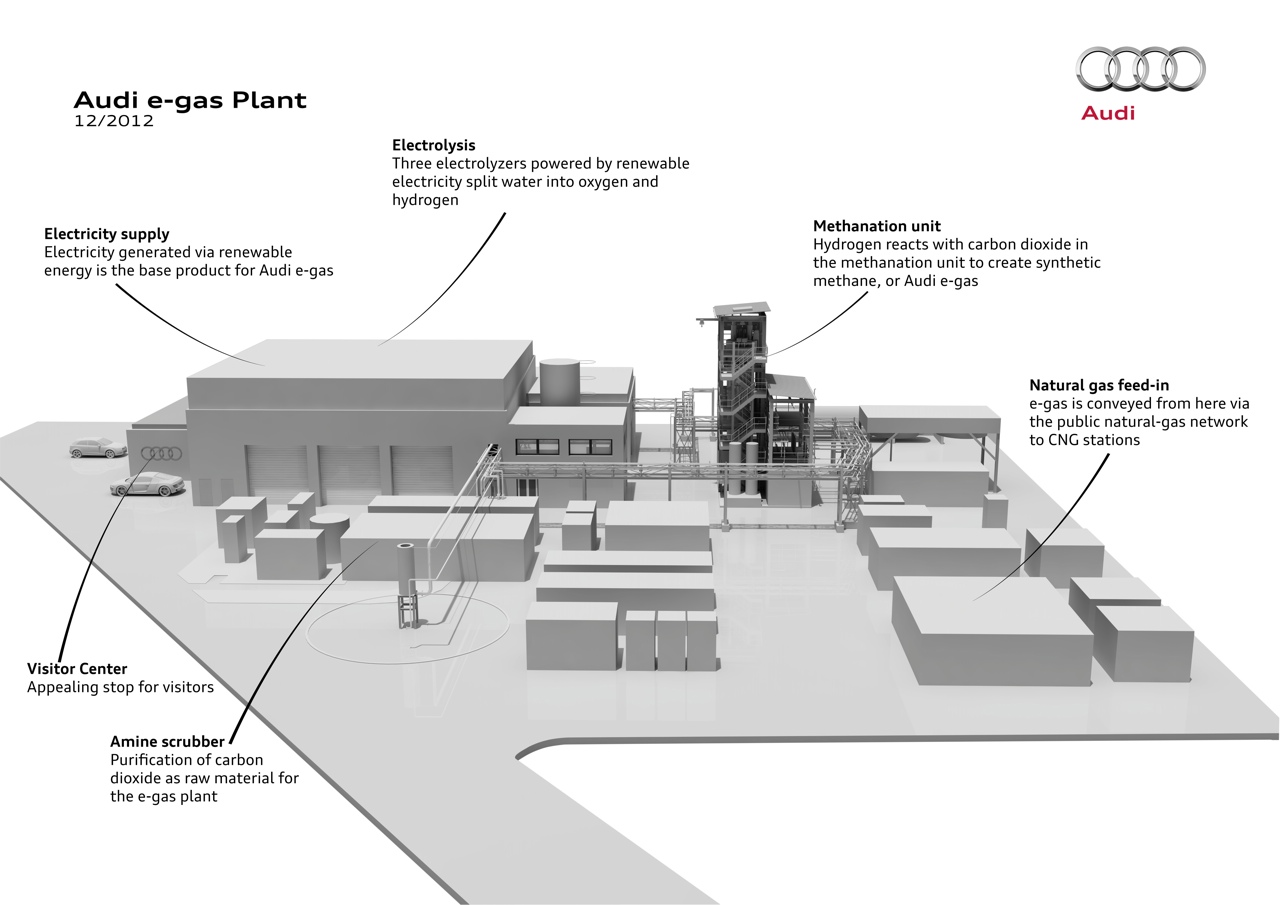

It is at this point most developers put their projects on hold, but Audi chose to make this futuristic technology work for the present instead. The sustainable hydrogen production facility soon to be opened in Werlte, Germany needs not run idle before its primary product can be directly utilised in transportation. By introducing CO2 to hydrogen they can create synthetic methane, which is chemically identical to natural gas.

The factory can convert about 2800 metric tons of the dangerous green house gas annually into up to 1000 tons of gaseous fuel. And we are talking about actual environmental clean-up here, since Audi will be using CO2 created in a nearby biogas factory as an unpleasant by-product of its operations.

By the time natural gas production gets under way all pieces of the puzzle will fall into place. By the end of 2013 Audi is launching the TCNG (turbocharged compressed natural gas) version of their A3 Sportback model, followed in 2015 by a similarly converted A4. The amount of gas annually generated in Werlte and then fed into the German gas network should be plenty to fuel 1500 units of Audi A3 TCNG for a whole year (based on an average annual mileage of 15000 km). While this is not quite enough to save the whole world, it is certainly more than a mere gesture made towards sustainable mobility.